Concept + Goals:

- Constructing an artificial, small-scale futuristic ecosystem under the scenario when synthetic biotic organisms are largely penetrated in human beings’ daily life.

- This ecosystem will trigger interactions between human and simulated biotic organisms to raise a discussion of individual bio existence and the ecosystem at a large scale.

-

A system that humans are party to, but not sovereign over.

Intended audience: I imagine this piece living in the gallery, the structures in this piece are seen not as inanimate, fixed objects, but as living entities, capable of regeneration and growth. The intended audience should be someone who is interesting in immersive installation environment and synthetic form.

Precedents:

A breath of life by Fraser Ross | Atelier

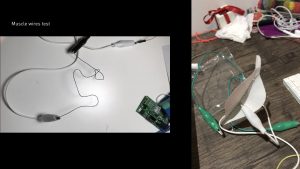

Muscle wire projects by Jie Qi

Description of the project:

A.Sketch

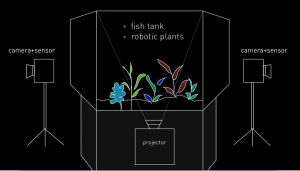

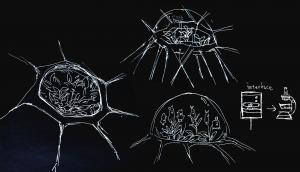

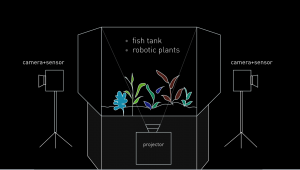

Before going into the implementation stage, I created sketches to illustrate the possible project scale and appearance. (Fig1.1)The outlook of the installation should look organic enough to make people think of cells or life form etc. Transparent glass and the customized base are being considered as important elements in this project, for both how it looks like as well as the setup detail. In Fig1.2., this diagram shows how this installation will be set up, and the layout of the components including robotic plants, camera or sensor, and projector. The camera will be used to capture audiences movements and the projector will be used to create an appropriate visual outcome. Since this is an interactive installation, the main input will be audience’s movement, which will trigger the robotic plants to respond to it. Robotic plants will be influenced by human factor, but will still have the random movement like real plants.

Figure 1.1. Project appearance sketch

Figure 1.2. Project setup and layout

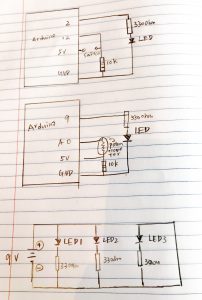

B. Technique

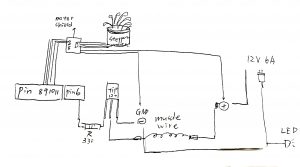

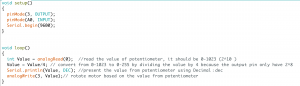

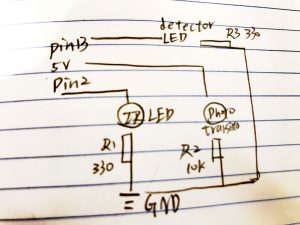

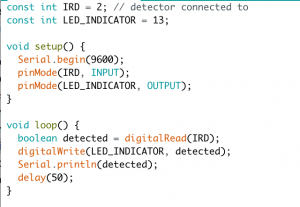

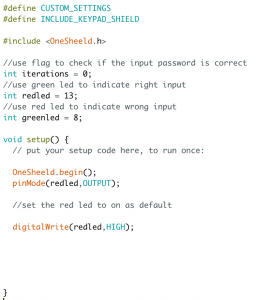

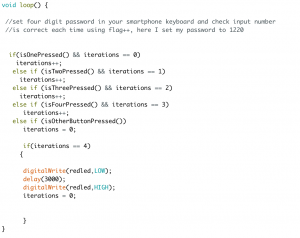

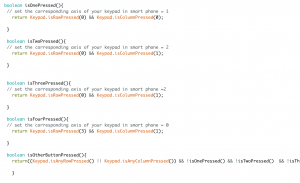

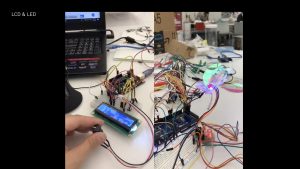

To generate a movement that is intriguing enough, the sensors in electronic components and multi-platforms are required. I want to connect Unity, Arduino, and Kinect these three platforms to complete the interaction. For each execution detail: Kinect– using the infrared camera to detect audience’s body skeleton and find the x, y, z-axis. Unity– using the c# program to enable the trigger function when audiences touch the certain area (there are five little yellow people models spread on the screen representing different location). When the models being triggered, Unity will send a byte to the serial monitor in Arduino. Arduino– in code, there is a processing message which will start to heat up the wire and rotate the motor, by typing “on” in the serial monitor, the function loop will start to run. To conclude, by connecting these three different platforms, I can achieve an indirect interaction without using a sensor. For the final setup, the audience will not see the unity interface so that they can just walk around, being captured by Kinect, and the robotic plants will move based on their movement without notice. The reason for putting all the technique together is to response the original idea for this project: a system that people can interact with in an indirect way.

C. Prototype and Playtest

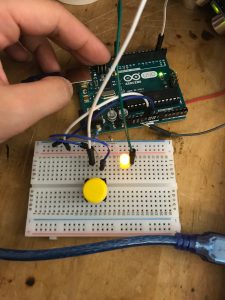

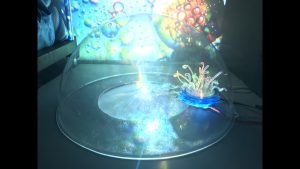

Through making a physical prototype, the main material for making robotic plants is the radiant acrylic. This is an important design decision being made— the acrylic itself representing cheap and mass production like what we can see in CD or any plastic product. However, the shimmer visual effect makes the robotic plant look futuristic, and it also fits into the context of “largely penetrate into our daily life”. I use laser cutting for customizing each plant, and also electronic components such as muscle wires, motors to create different movement.

Figure 1.3. the first physical prototype with radiant acrylic and stepper motor

After the very first prototype, I found out the movement of the motor is too stiff, and I need to find the other components that can create natural movement. The muscle wire is what I chose in the end. It is a unique type of wire that acts like the muscles in our bodies. Muscle Wire is an extremely thin wire made from Nitinol (a nickel-titanium alloy) that is known for its ability to contract when an electric current is applied. I incorporated this component to my project, and there are some interesting precedents created with muscle wires that I got the inspiration from. For example, A breath of life by Fraser Ross, using Flexinol, recycled electronic components, specimen jars, these “flower lamps” reside in a state of death until human interaction — a breath — brings them to life for a brief moment. The blowing is the appropriate interaction as trees and plants grow on carbon dioxide. Every living thing needs a home, plants change themselves to survive in their habitat.

Figure 1.4.”A Breath of Life by Fraser Ross.”, 2010.

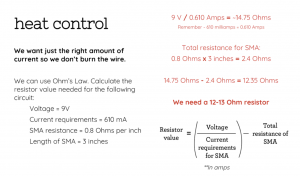

For my own creation with muscle wire, I tested out several prototypes to make a real-life look based on the shape of real plants, like a leaf, flower, and Venus flytraps (FIG 1.5). Using muscle wire is the most challenging part of this project, it’s really difficult to manage the right amount of electricity and there are countless wires to put together. However, after series of tests, I put all the components together and add the light effect to see the real set of the project and then conducted a primary playtest. At this stage, the primary project form and the aesthetics have already come out.

muscle wire movement prototype- venus flytrap

Based on the feedback I got from playtest, there are two aspects needed to be improved: first, the movement of wire and plants are not that clear, the movement is sparse and too gentle to notice. Second, the layout of plants are not well-formalized, they looked like individuals rather than a whole ecosystem.

D. Finalise

Consider the setup for the exhibition, I made a customize stand to store projector and all the electronic components inside. One another important decision is that I used transparent acrylic to reveal the wires and the circuits of this projects because I want people to feel the technology behind this piece as if those wires are the origin of robotic plants. Also, the depth camera used to capture human beings’ movements are decorated with robotic plants in order to make it fit into the project.

Figure 1.5. decoration on the depth camera

Reflection

The criteria used to evaluate this project is mainly based on visitors’ behavior during the major major exhibition. The most frequent feedback I got from this project is that people enjoy its aesthetics, including lights and handcraft robotic plants. At the same time, people do feel want to interact with it and see what will happen, and they will want to dig more into the concept behind. The whole interaction takes people for 3 mins on average. Most of the feedbacks are positive, but one thing I think should be improved is that some people will neglect the movement because it happens randomly and there is no clear light resource to light up each component. The future iteration of this project will be the reassessment of the project scale, maybe the large scale living system can provide a more immersive experience.

List of components:

- Arduino Mega2560

(there are more pins on Mega which enables me to connect 6 muscle wires, 1LCD, 8 LED lights, and 1 stepper motor, the total number of pins in need is 34. )

a nice substitution for Kinect, lightweight, easy to set up, and compatible with Mac environment. I was supposed to use Kinect 2 to track people’s skeleton but my windows laptop broke the night before the exhibition, so I change unity to openframework and Kinect to depth camera to create the desired outcome.

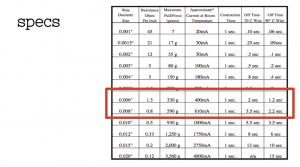

I bought tons of them on sparkfun. There are different specs and I think 0.012″ looks good, not too thin or too thick.

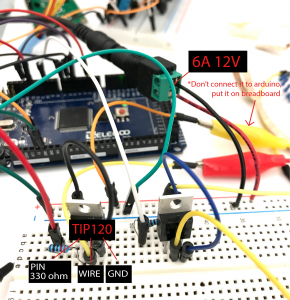

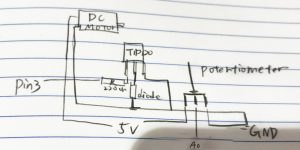

- tip120

- 330-ohm resistor

- 12v stepper motors

- motor shield for stepper motor

- 12v 6a power sourcex2 – each for heating up 3 muscle wires

Presentation slides and Process:

Additional resource: For this project, I tried to gather all the useful information about using muscle wires, and I put them all in a google doc

Code: Code in Arduino on the GitHub