Week 6: Making my own piano

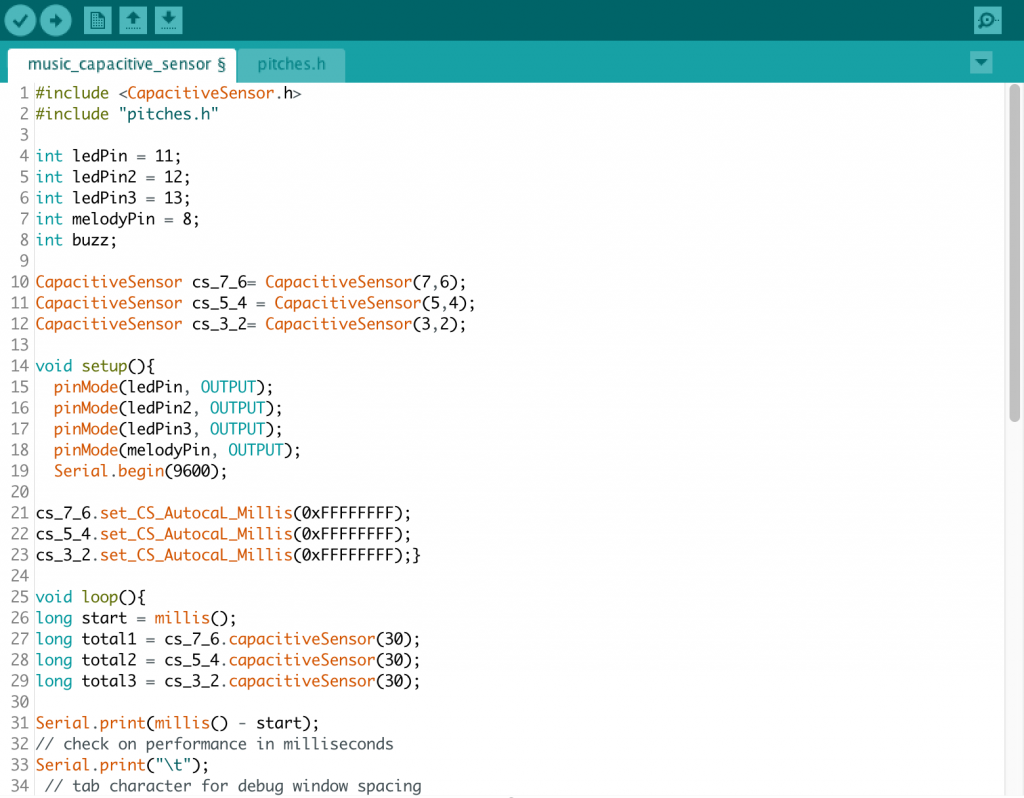

This week’s assignment was to creatively rethink how sound and/or light could be incorporated into projects by modifying the input sensors. I decided to work with capacitive sensing because I love the possibilities it provides. It allows us to make our own sensors and enhances the quality of the interactive experience.

List of Materials

1 x Elegoo Uno R3

1 x Full sized breadboard

1 x Piezo buzzer

3 x Graphite strips

3 x LEDs

Resistors: 3x 220 Ohms (for the LED), 3 x 1 Megaohms (for capacitive sensing)

Jumper wires

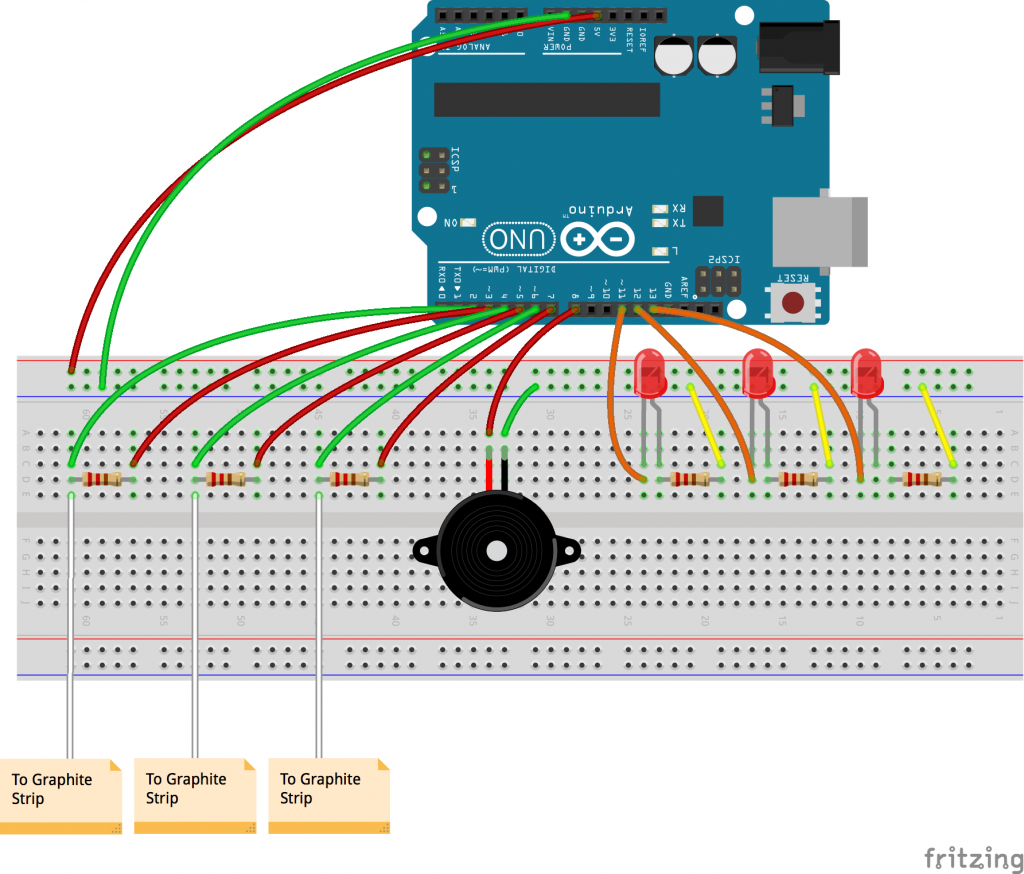

Fritzing diagram

Description of assembly

- Connect the ground side of the breadboard to the GND pin, and the power side to the 5V pin, on the Arduino.

- Add three LEDs to the circuit, with the shorter legs connected to the ground via 220 Ohm resistors, and the longer legs to digital pins 11, 12 and 13 respectively. Connect the Piezo buzzer with the ground connected to the ground of the breadboard, and the power to digital pin 8. Both the LEDs and the buzzer act as the output, reacting to changes in the capacitive sensors.

- To make one capacitive sensor, connect two jumper wires on either end of a 1 Megaohm resistor to digital pins 2 and 3. The resistor leg, connected to pin 2, should also be connected through the jumper wire to the graphite strip.

- Repeat step 3 two more times, using digital pins 4, 5 and 6,7.

- Upload the code to the Arduino IDE.

- Debug, check connections and keep working!

How it works

Capacitive sensing works on the principle of using a conductive material to complete the circuit. This circuit works as follows. A high resistance of the order of a megaohm is placed on the breadboard, both ends of which are connected to say, digital pins 2 and 3. Digital pin 3 acts as the input and allows a steady stream of electrons to flow through the circuit. The resistor inhibits the flow and only lets a small number of electrons pass through the other end. The other end in addition to being connected to a digital pin is also attached to a jumper wire. When we touch the metallic end, we pass on a large number of electrons from our body to the circuit. The Arduino can sense this change and can be coded to control an output by defining a threshold value.

Iterations

Graphite conducts electricity and this property can be utilized in interesting ways. I shaded some bits of paper with an HB pencil and connected them to the breadboard so that they could act as switches. For the first iteration I decided to make an instrument where, on pressing each key, one would hear a different, pre-programmed song through the Piezo buzzer. I first tried with the example code melody to see whether all three switches were working individually. On graduating to coding different songs, I had limited success.

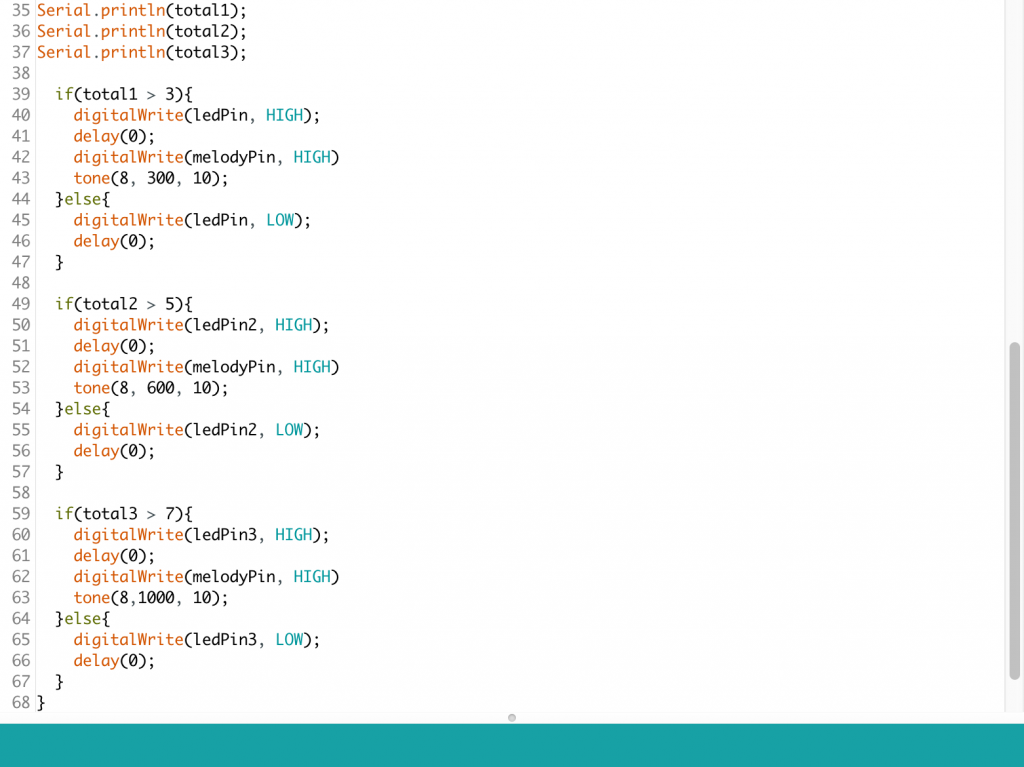

This further led me to think about how a user could make their own music. On pressing a key, they would hear a tone, akin to a piano. The various sequences and combinations could culminate in unique tunes. I had trouble associating one LED to one graphite switch. After multiple iterations, it turned out to be a glitch in the code which I then rectified.

Code

Motors – Dario N (Week 8)

Stepper Motor + Water Level Sensor – Dario N (Week 8)

Goal of the Project:

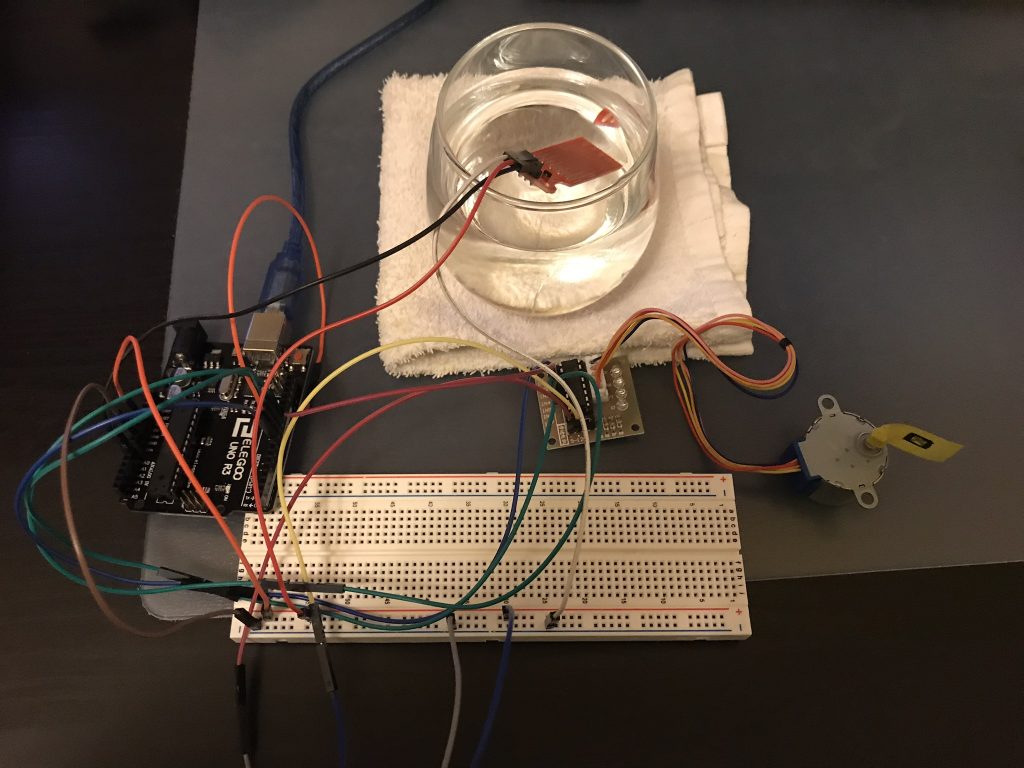

With this project, I wanted to explore a new and rare sensor as a trigger/switch for a stepper motor. In this case, I used a ‘Water Level Sensor’ to tell the Motor when to turn on and off depending on how deep the sensor was into the water. I wanted to challenge myself into going to use new tools and hardware.

List of Components:

- x1 Arduino Uno

- x1 Breadboard

- x1 Water Level Sensor

- x1 Unipolar Stepper Motor

- x1 Stepper Motor H Bridge

- Jumper Wires

Assembly Process:

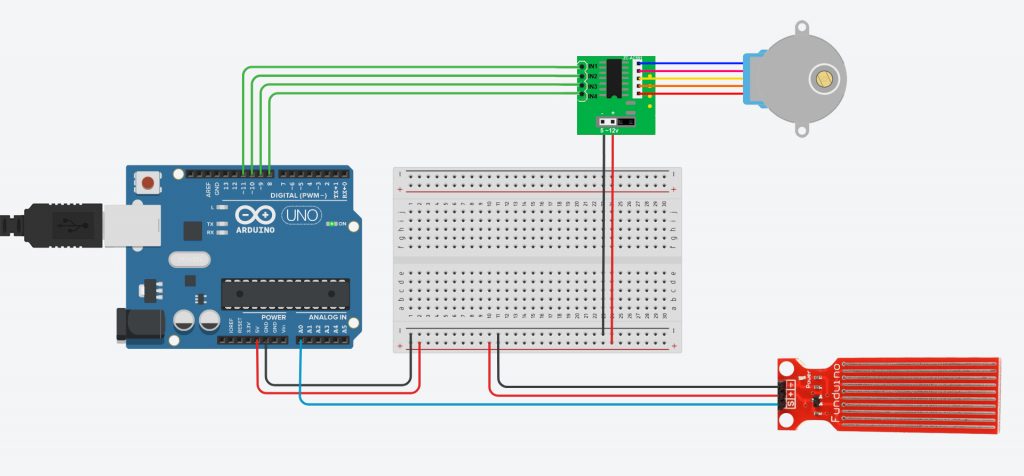

To create this project, first, I checked that the water level sensor was reading the analog data as soon as a submerge it into the water. I simply connected the jumper wires to the 5V, the ground and to the analog read. Then, I connected the stepper motor to H-Bridge and into the Arduino to pins 8-11.

How it works:

The Arduino is constantly reading the input data from the Water Level Sensor. 0 means that the sensor is out of the water; as soon as it gets submerged the data start bumping up to approximately 400. I used this value to tell the stepper motor when to turn on. It is also possible to modify the direction of rotation depending on the range of values from the sensor. There are infinite possibilities! I imagine using this scheme in applications such as in boats, aquatic designs. I quite like the idea of using the water as a trigger. What if the sensor is a trigger to create a musical instrument were the water is the medium?

Problems:

I had some issues with the coding part. The water sensor was giving me values every second when It was by itself. But as soon I connected the motor, it started reading every turn which is not ideal. I couldn’t solve this issue with coding. I had to increase the speed of the motor, so the reading happened quicker.

Arduino Code (File):

https://www.dropbox.com/s/vlz4gihrfu8y3ro/Stepper_Dario.ino?dl=0

Circuit Diagrams:

Resources:

http://engyfun.blogspot.com/2015/02/here-is-source-code-for-our-28byj48.html

https://github.com/joycemolly/stepper-motor-and-h-bridge/blob/master/sketch_mar13a.ino

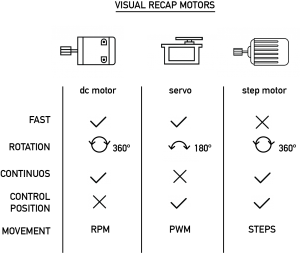

VISUAL RECAP MOTORS – Carla Molins

Servo Motors (Week 8)_Alyssa

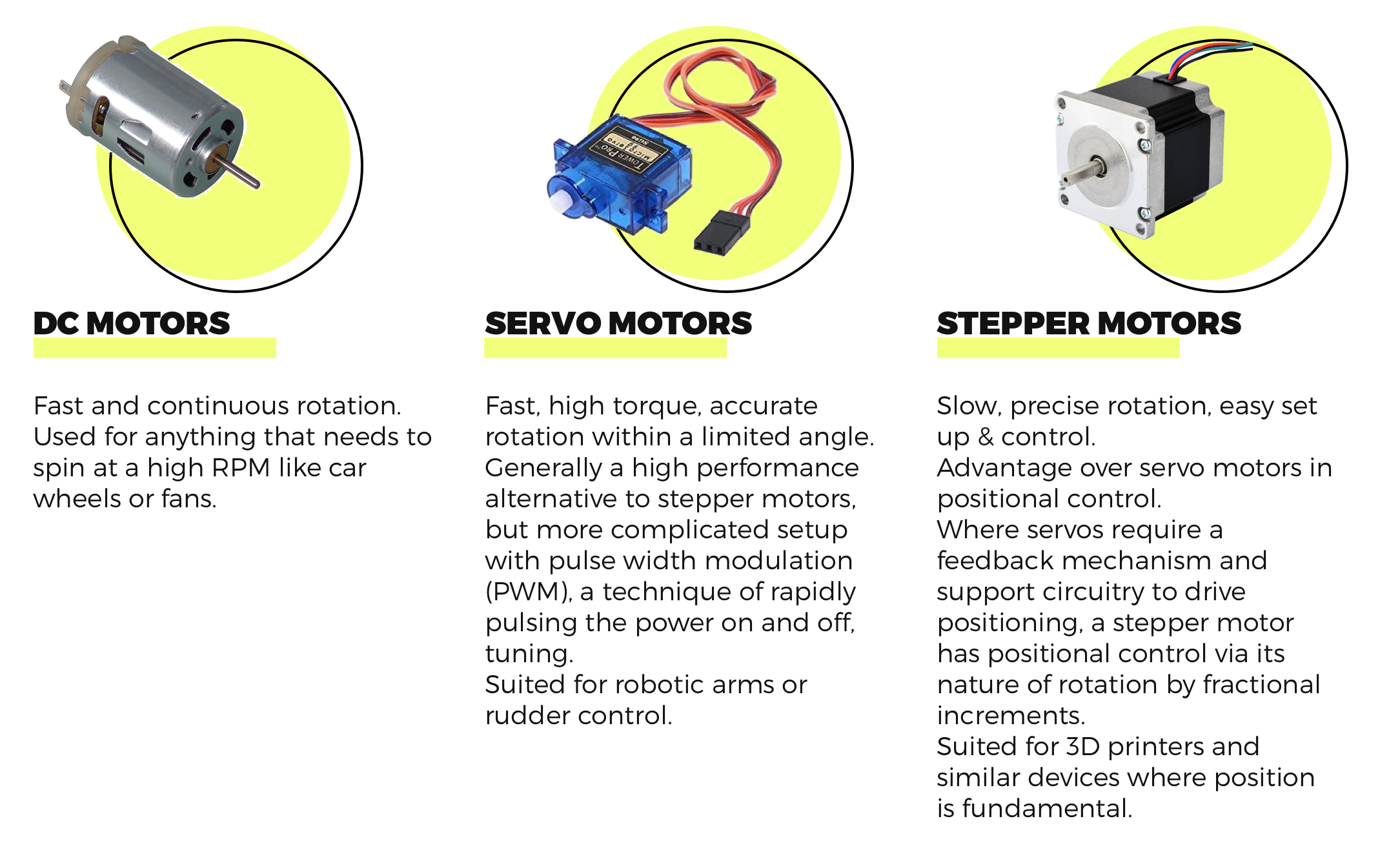

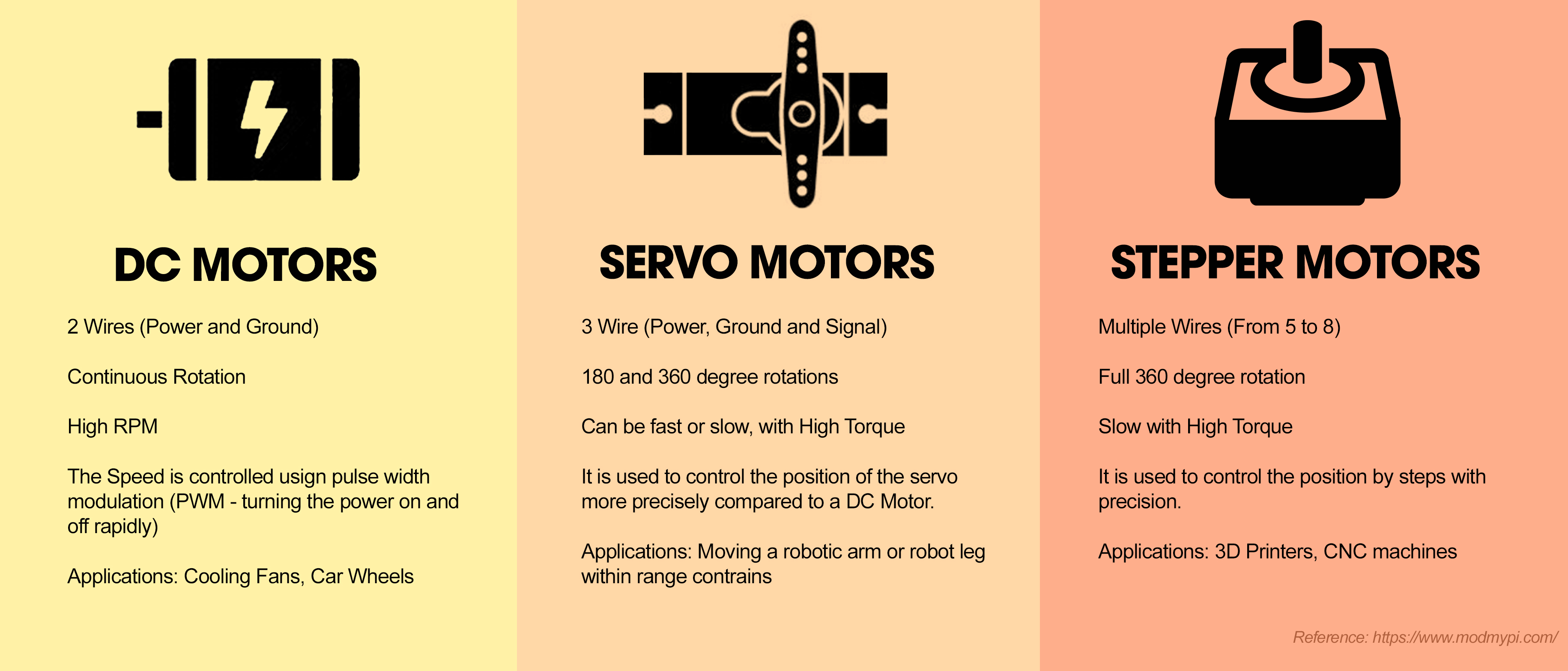

What are the different motors?

DC motors rotate continuously. Their speed is controlled by PWM, which actually turns the motor on and off so rapidly it looks like a smooth movement. DC motors rotate until power is detached.

Servo motors are good for exact tasks because they can be more precisely controlled than standard DC motors. Power to the motor is constant but regulated by the servo control circuit. PWM “unlike DC motors it’s the duration of the positive pulse that determines the position, rather than speed, of the servo shaft.” (source: https://www.quora.com/What-is-the-difference-between-a-DC-motor-a-servomotor-and-a-stepper-motor)

Stepper motors use electromagnets around a central gear to determine the position. Each electromagnet must be individually powered to make the motor shaft turn.

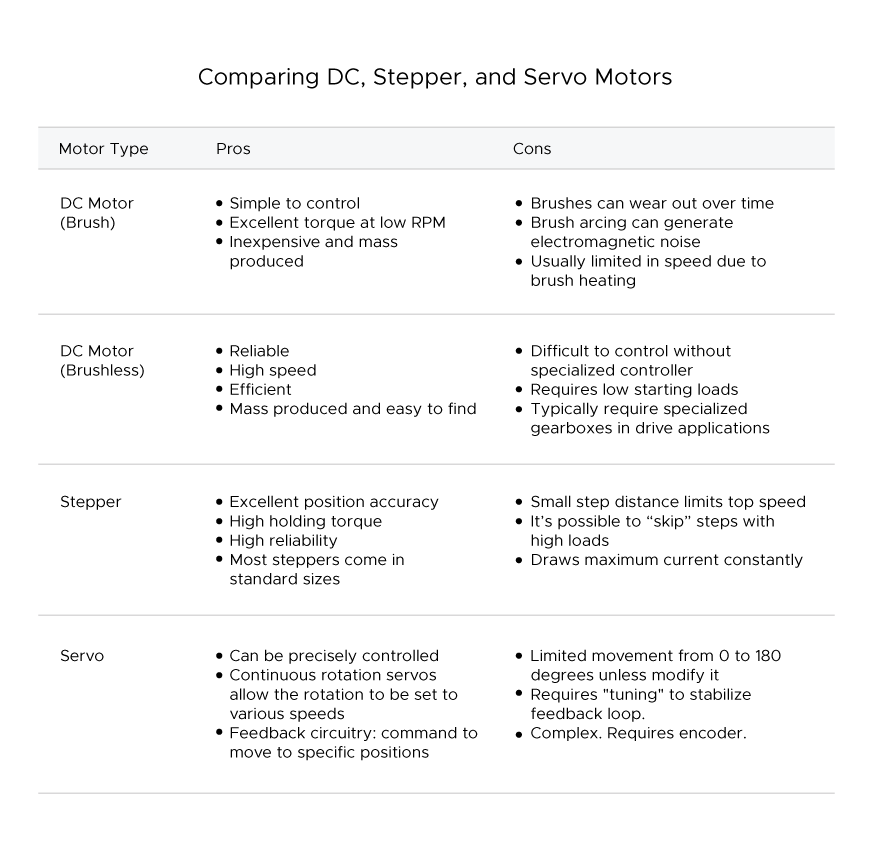

Comparing DC, Stepper, and Servo motors (Week 8)

DECISION BOT 1.0 – Carla Molins

- Goal of the project and/or desired interaction

My main goal was to overcome a past frustration using the servo motor. Decision bot 1.0 aim is to help us make those daily complicated decisions such as: “Should I have another coffee?” or “Should I eat a cookie?”. (My roommates asked more interesting questions though).

Week 8 – part 2

Goal of the project : create a robotic ouija board

Core components : servo motor, arduino, a button and a resistor

How it works : when the button is pressed the robotic hand moves randomly to a 0-360 degree pointing to one letter at the time

Arduino code:

Continue reading

Week 8 – part1