Summary

I’ve been excited all semester by a the freedom to really rethink what familiar hardware could look and feel like: when the components are small enough, or bendy enough, or crafted just right– can we make familiar hardware radically different? What new experiences do we get as a result?

With that in mind, I turned to speakers. My goal for this final project was to create a functioning speaker that looks and feels nothing like the speakers that we know. Unlike most speakers, mine would be soft, squishy, organic, colorful, and weird.

Below is a short summary of my work, one component of which contains an Instructables link for a detailed how-to.

———————————————————————————————————————————

Part 1: early explorations

I chose to use wool as my main structural material: it was soft but still had some structure, could be sculpted into organic shapes, came in various colors, and could withstand heat from small electronics.

In these first component prototypes, I created a pressure sensor (orange and blue) and a speaker “swatch” (green and red) using wool, conductive thread, velostat, and neonymium magnets. I’ve described the detailed process for the pressure sensor as an Instructable.

———————————————————————————————————————————

Part 2: middle explorations

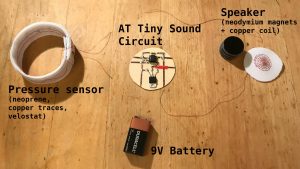

After getting familiar with the materials, I moved towards making a single shape that included all three of my speaker components: a pressure sensor, a speaker, and an AT Tiny sound circuit (diagrammed here), and referenced again below.

Components

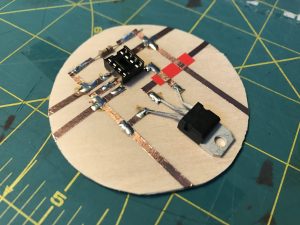

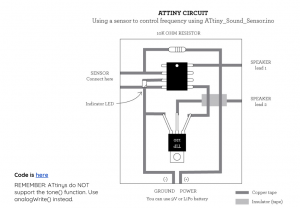

AT Tiny Circuit details

Modeled after class slides (slide 56), this circuit includes an AT Tiny, 10k Ohm resistor, and a TIP 120. All components are connected with copper tape (soldered where needed). They rest on a super thin piece of birch wood, so that the circuit stays flat even when the speaker is squished.

Here’s the bad news of this post and my final: my circuit / code isn’t quite working. I’ve tested connections, sensors, mixed and matched various components, but the debugging continues past due date. I’m determined to figure it out, but for the sake of submission, I’ve completed the other components to give a feel for the final imagined product. My code uses analogWrite() in the same manner as the template here.

Pressure sensor details

Two strips of neoprene, each with copper thread sewn onto one side using a couch stitch. THe two layers are then sewn together, copper tape facing inward, with velostat between (shown partway assembled above). The entire strip is then made into a circle, shown in the Components diagram above.

Speaker details

The speaker’s main components include a stack of neodymium magnets and a copper thread coil sewn into a swatch of neoprene.

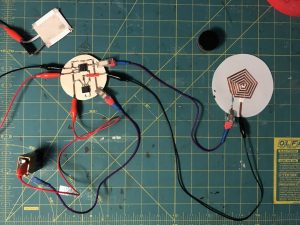

Assembly

All of these components, when assembled, sit inside a felted wool body.

AT Tiny circuit goes in the main body

AT Tiny circuit goes in the main body

Pressure sensor wraps around main body

Pressure sensor wraps around main body

Magnet and coil get their own body

Magnet and coil get their own body

Magnet and coil body connect to main body

Magnet and coil body connect to main body

The rest is aesthetic…

The rest is aesthetic…

———————————————————————————————————————————

Part 3: future

I’m determined to get this working properly, maybe even through a final iteration that takes the best of all my prototypes so far.