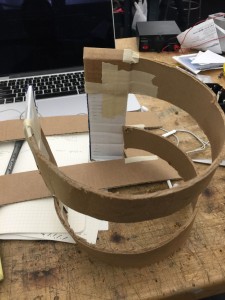

We started with a rough cardboard prototype to get a size and positioning reference.

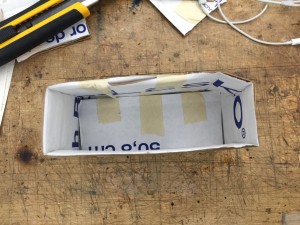

From there we began working on a neck piece that would control and/or turn on the helmet device. It consisted of materials such as plastic, metal (aluminum and copper) and foam.

Here we used the PVC pipe to shape the form of the metal to best fit our needs.

Below is the plaster moldering process.

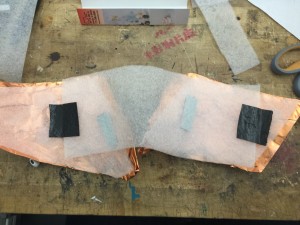

Here we moved to using .003mm copper sheets.

Finally we began working with a capacitive touch sensor