Final Project Proposal

Here’s my proposal for today:

In our group we discussed ways to reverse the thermochromic reaction. Since I’m looking to create a shading device, I want the shading material to become more opaque as the light/heat increases. To do this, we either thought I could run current through the fabric and have it shut off when a temperature sensor reached a certain high temperature, or that I should look for a material that behaves the way I want to begin with!

There is a way to reverse the thermocromic process and make it a film, which is used in thermochromic windows that remind me of those transition lenses people used to wear, where they looked like regular glasses when they are indoors, but when they went out into the sun they became sunglasses!

This is the effect I’m looking for, but I’m not sure how to duplicate it myself:

http://youtu.be/WylYlPfXxJ4 (@55 sec)

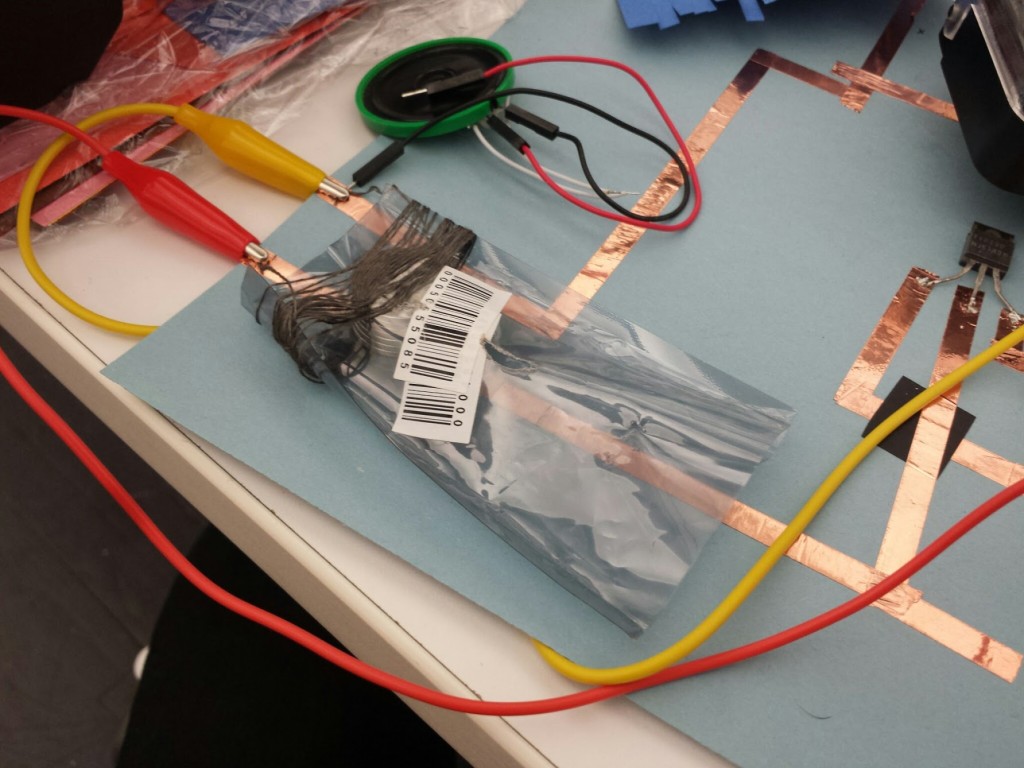

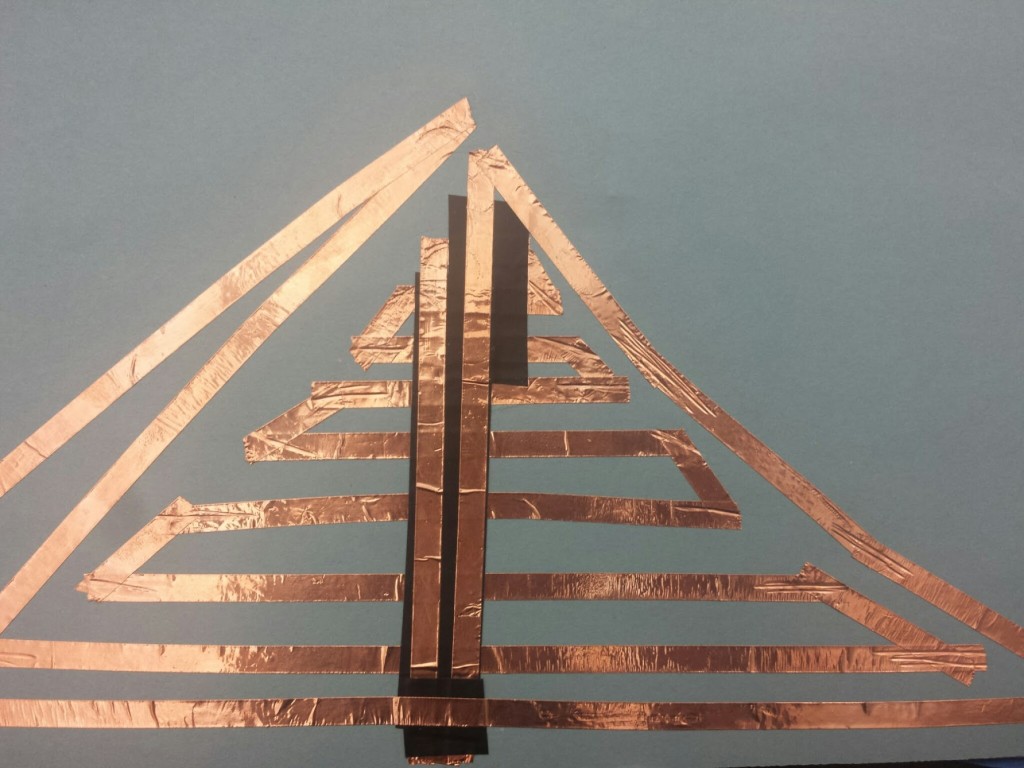

Speaker Attempts

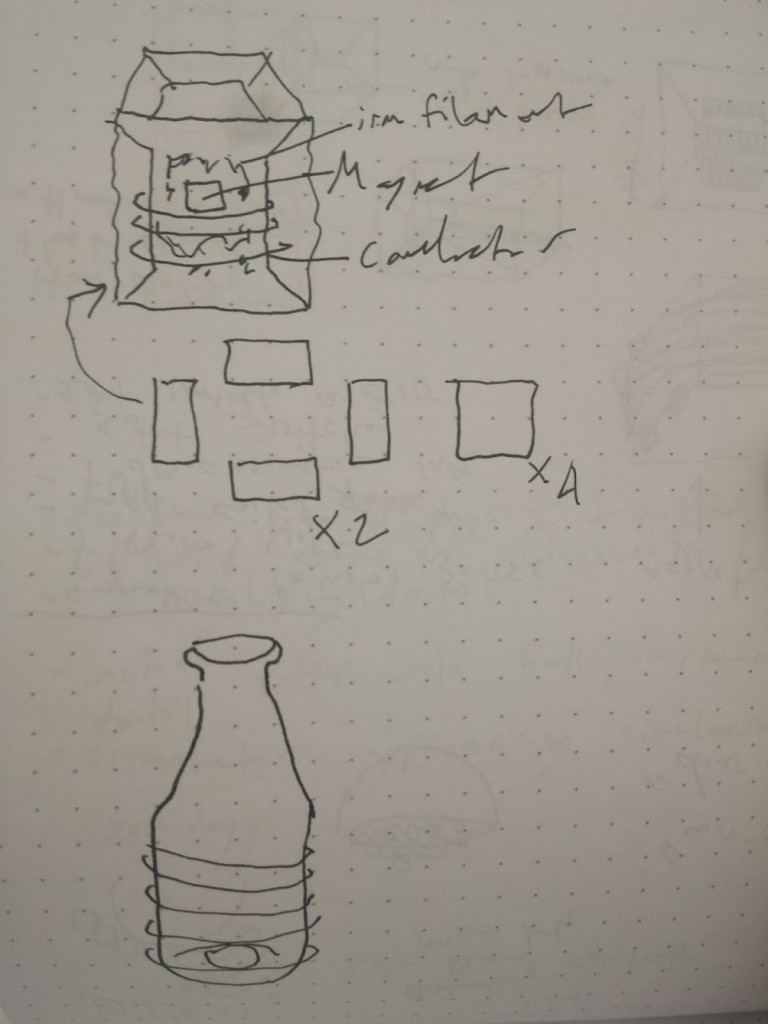

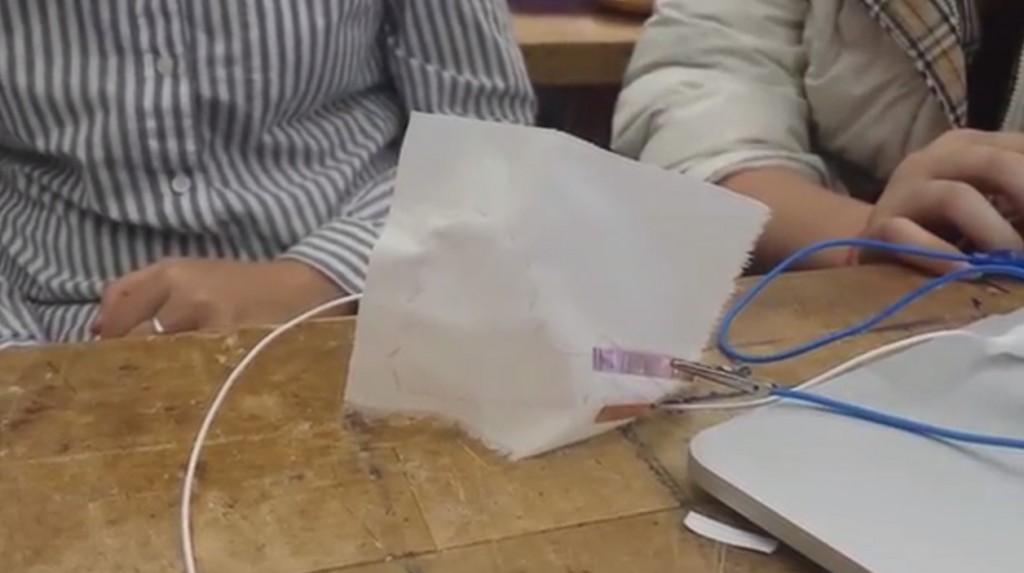

The first attempt was made using copper tape on paper in a mountain-ish design. This one didn’t end up working. I’m guessing this was caused by too many separate strips of copper tape. The second attempt, made with Xiaoqi was made of paper with strips cut either side (not pictured). In each of these cuts, conductive thread was wrapped around. This created a very subtle sound, yet was much easier to create than the copper tape speaker. The final one I made was created using a small bag in which the magnets were placed, with conductive thread wrapped generously around it. This one worked the best, which is funny, because I didn’t realize I was using an anti-static bag. It would seem as though static electricity and electromagnetic forces might not interfere too much.

Final Proposal

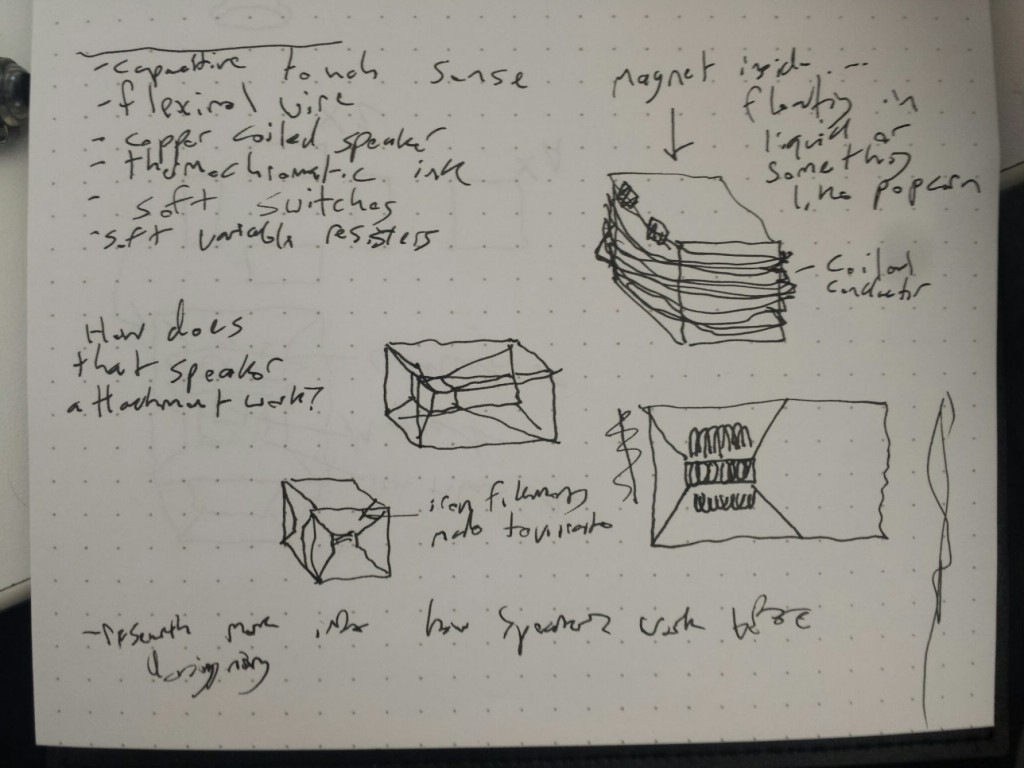

Originally inspired by the possibilities for speaker design with copper tape, I started thinking about different ways to make this interesting. My first thought was to make a laser cut enclosure with a magnet in the center, separated by transparent plexi from some sort of conductive material coiled around the outside. I considered having this either float in a liquid or possibly some kind of light material, such as popcorn or packing peanuts. I thought it also might be interesting to see what would happen with iron filaments in there as well, whether they would be able to visualize the oscillating magnetic forces involved. Discussing it with my peers, I was reminded of the capacitive sensing we did earlier in the course and was also referred to this project. Perhaps it will become some kind of theremin, which could be interesting, but would be challenging to institute an original take on.

Thermochromic Ink

Flexinol Movement

Here are the videos of the flexinol muscle wire action. The weight of the canvas material probably held back the movement, but it seemed better with a little help from gravity.

Videos:

https://plus.google.com/100428831157187826962/posts/cWjSL63zUAW

https://plus.google.com/100428831157187826962/posts/RP6khX4nfJm

Flexinol Assignment

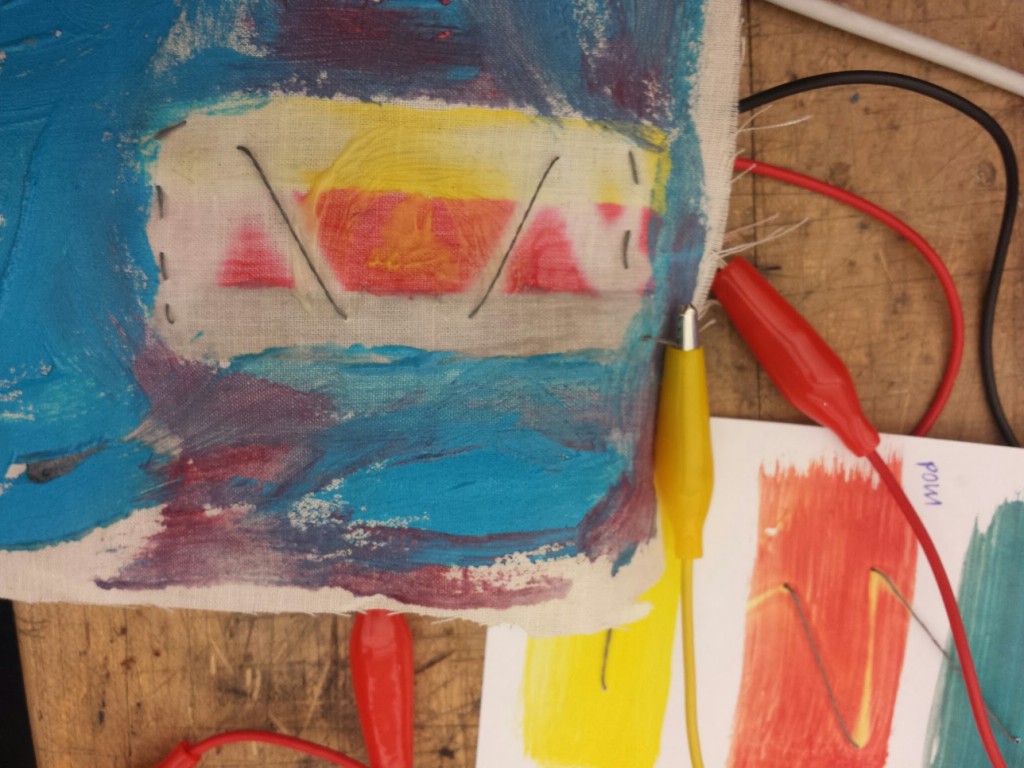

I wanted to create a breathing effect with the fabric, so I sewed the flexinol wire directly to the fabric and connected it to the Arduino using alligator clips and jumper wires. When I ran the Fade example sketch, it worked (eventually)!

Flexinol Circuit

Denah and I trained a piece of flexinol by wrapping it around a pencil and heating it up. Then we sewed it into the hem of a black dress. we sewed some red string so that it would be easier to see the movement. We connected the ends of the flexinol to alligator clips and to the positive and negative sides of a battery. Watch it move!

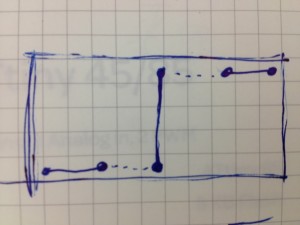

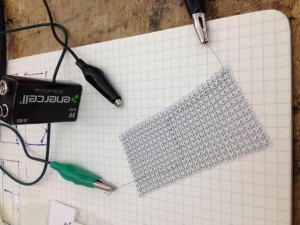

Wire

I’m interested in the affects of the muscle wire on textiles, which is always easier to measure on a grid, so I used a sample of a linked metal mesh to test it. I laid out the wire into 3 connected segments.

I just tested it with a battery, I assumed correctly that the mesh was a bit too heavy for the wire to really move, but it did twitch a bit!

Jessica

Thermochromic Ink

I was really interested in creating more of a volume with the thermocromic ink, so I tried mixing it with bioplastic

4 Tbsp. water

1 tsp. gylcerin

1 tsp. white vinegar

1 Tbsp. corn starch

Combine ingredients in a sauce pan and cook over medium high heat until the mixture becomes clear and begins to bubble. Mixture will be more solid them liquid. Spread onto a silicone sheet or tinfoil in a thin even layer. Let cool for a few hours.

I think I let the bioplastic cool too long before pouring it onto the plastic and ink powder, so it didn’t spread as evenly. It still reacts to the heat, but I’m hoping for something more dramatic and spacial. I’m hoping to do something related to shading devices and maybe making it deployable for the final project which relates to my thesis of textiles in/as/in architecture.

Jessica