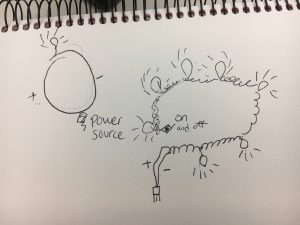

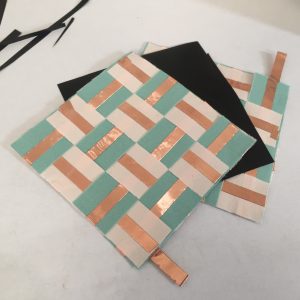

For this week’s assignment, I’ve decided to create a stroke sensor. Instead of using store bought conductive yarn, I decided to make my own. (I didn’t have any conductive yarn handy, and I had lots of conductive thread available.) I did this by braiding non-conductive yarn and conductive thread together.

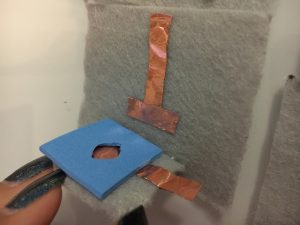

This is the first stroke sensor I made. It worked well, but the thread and yarn untangled from each other.

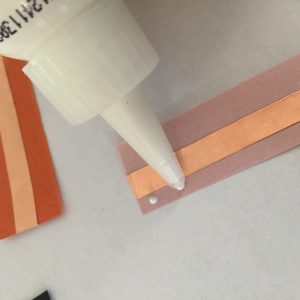

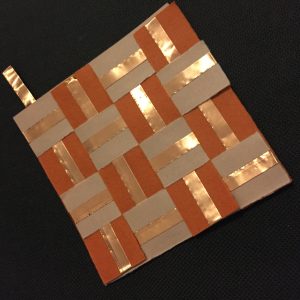

For the second one, I glued the tips together. This worked in keeping the two together. In the first sensor, I glued the conductive fabric to the back of the felt. I wanted to try sewing the two pieces together in the second one and see what kind of results I would get. As it turns out, it worked just as well, and it was much easier to sew all the pieces together. By sewing the pieces together, it also allowed me to customize the sensor a little more.

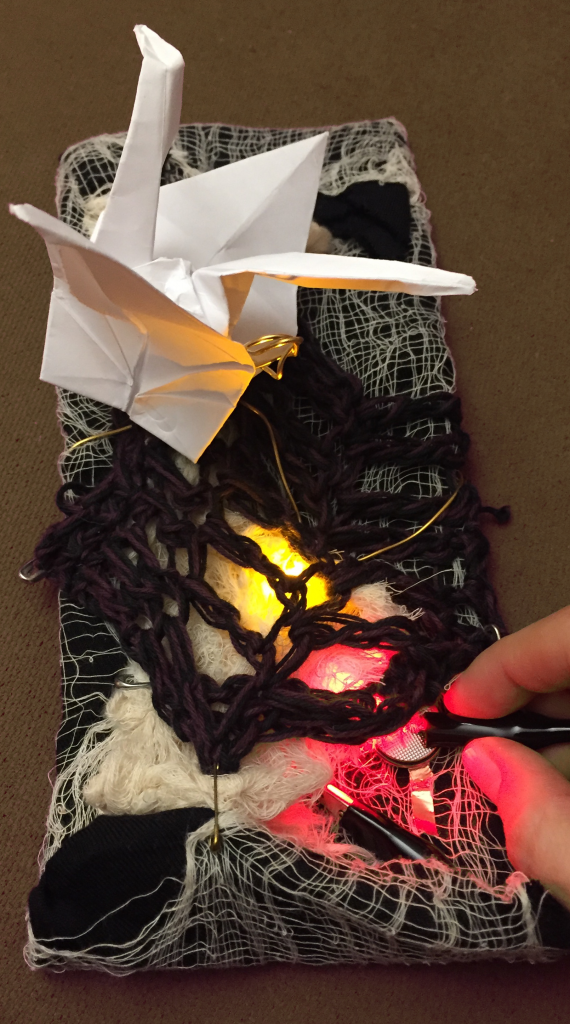

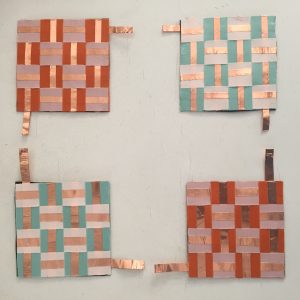

For the third sensor, I decided to try different methods of using the materials. I left the thread open and I added non-conductive yarn in the middle. This didn’t work as well because the thread is exposed, and it was easy for the two sides to make a connection.

For the last one, I decided to try another type of yarn. This one was hard to use because it the yarn was much thicker. I decided to leave the middle open because the thread was insulated enough as is.